Advantage of Using Industrial Cutting Tools

Though there are no scarcity of gadgets or devices made use of cutting and shaping in manufacturing industry, there is still increasing demand of such devices that can assist make various cuts with greatest accuracy's, taking a little time as far as possible. With flooding of cutting devices on the marketplace, it is hard to come with the finest one if you do not understand completely about various types of tools. This is what worries making market associated with producing products that require different sort of hack and shapes. Here is the best ways to discover the one that simply deals with your needs.

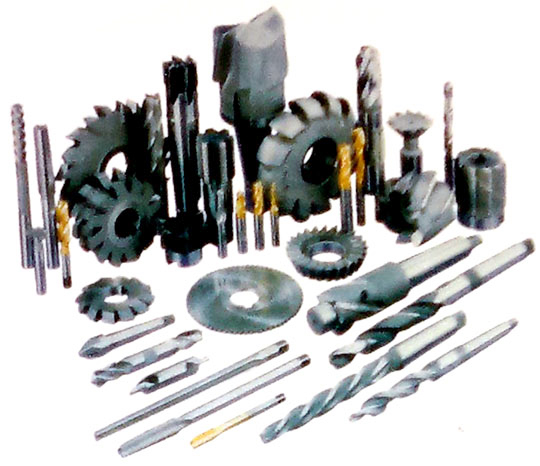

As different kinds of material have different hardness, they need various cutting tools to be cut into numerous shapes. Take aluminum for instance which can be cut and easily formed in any shapes through end mills with variable flute taking fairly less time to cut through the product. Though looking just like a drill a sort of cutting tool, it is entirely various from that in regards to its applications, design and manufacture. As it is made from carbide, a material with higher hardness and able to cut metal without breaking or scratching, the device is likewise referred to as carbide end mills. It can be found in different types with several flutes also known as helical grooves allowed to move the cutter up and down.

What make the tool most searched for in the industry needing cutting and shaping on various products are its capability to cut precisely and give more refined finish as compared other tools. For which the device comes flutes with sharp teeth, which help to cut through the material, making chips fall away from the cutting surface by the rotation of the flutes. In addition due to the fact that of its helix shape, the tool is extremely capable to give a more sleek finish by lowering the vibration.

Buy carbide spot drills online, which are made from high quality product particularly micro grain carbide and created for finding applications which enhance accuracy of hole allocations. They feature 2 flutes of lengths while overall length of the flutes is 2.0. Making different cuts and shacks on various products and the method they to be crushed, there are lots of kinds of carbide end mills in various shapes and geometries. For example, for difficult product such as stainless steel, end mills with shallow flutes work well. While for the product like aluminum, strong carbide end mills with deep flutes with sharp cutting edges make the perfect device for cutting and shaping needs.